Bruker's differentiated high-value life science research and diagnostics solutions enable scientists to make breakthrough discoveries and develop new applications that improve the quality of human life.

Driving profitable growth

We create opportunity for scientific discovery, creating sustainable value for our customers, employees and shareholders.

Creating a sustainable future

Our advanced instrumentation enables scientists across the world to improve the quality of life for the global community.

Our Business Groups

We are a developer, manufacturer and distributor of high-performance scientific instruments and analytical and diagnostic solutions that enable our customers to explore life and materials at microscopic, molecular and cellular levels.

About Bruker Corporation (Nasdaq: BRKR)

Bruker is enabling scientists to make breakthrough discoveries and develop new applications that improve the quality of human life. Bruker’s high-performance scientific instruments and high-value analytical and diagnostic solutions enable scientists to explore life and materials at molecular, cellular and microscopic levels.

In close cooperation with our customers, Bruker is enabling innovation, improved productivity and customer success in life science molecular research, in applied and pharma applications, in microscopy and nanoanalysis, and in industrial applications, as well as in cell biology, preclinical imaging, clinical phenomics and proteomics research and clinical microbiology.

Today, worldwide more than 6,900 employees are working on this permanent challenge at over 90 locations on all continents. Bruker continues to build upon its extensive range of products and solutions, its broad base of installed systems and a strong reputation among its customers.

Being one of the world's leading analytical instrumentation companies, Bruker is strongly committed to further fully meet its customers’ needs as well as to continue to develop state-of-the-art technologies and innovative solutions for today's analytical questions.

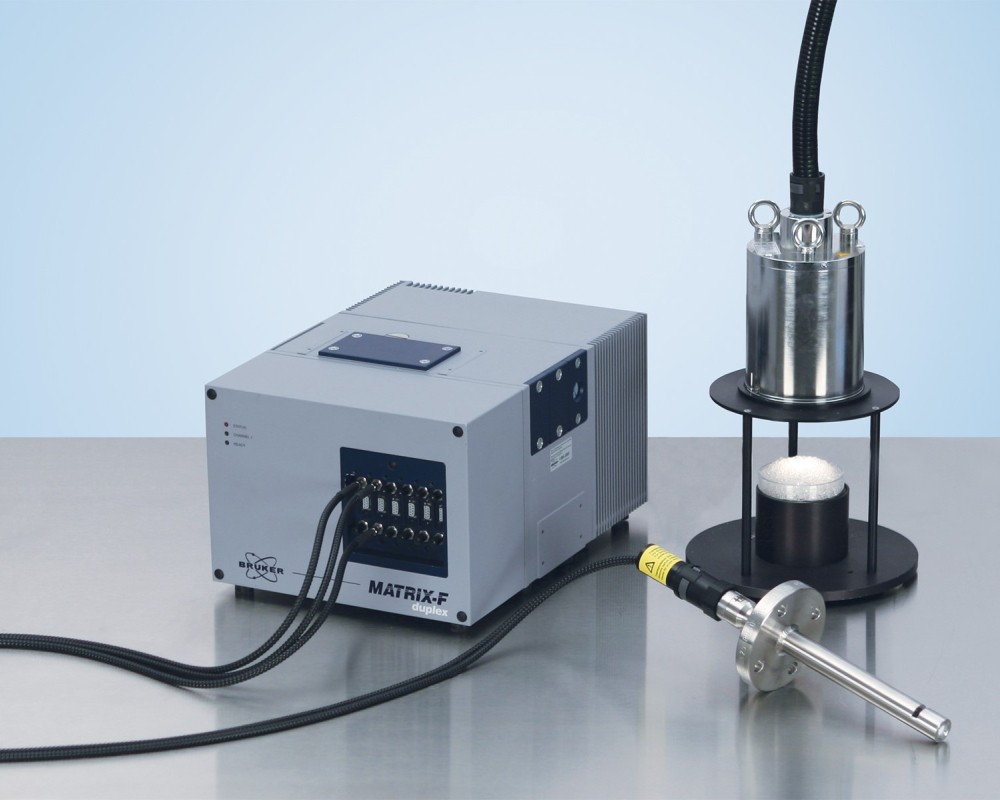

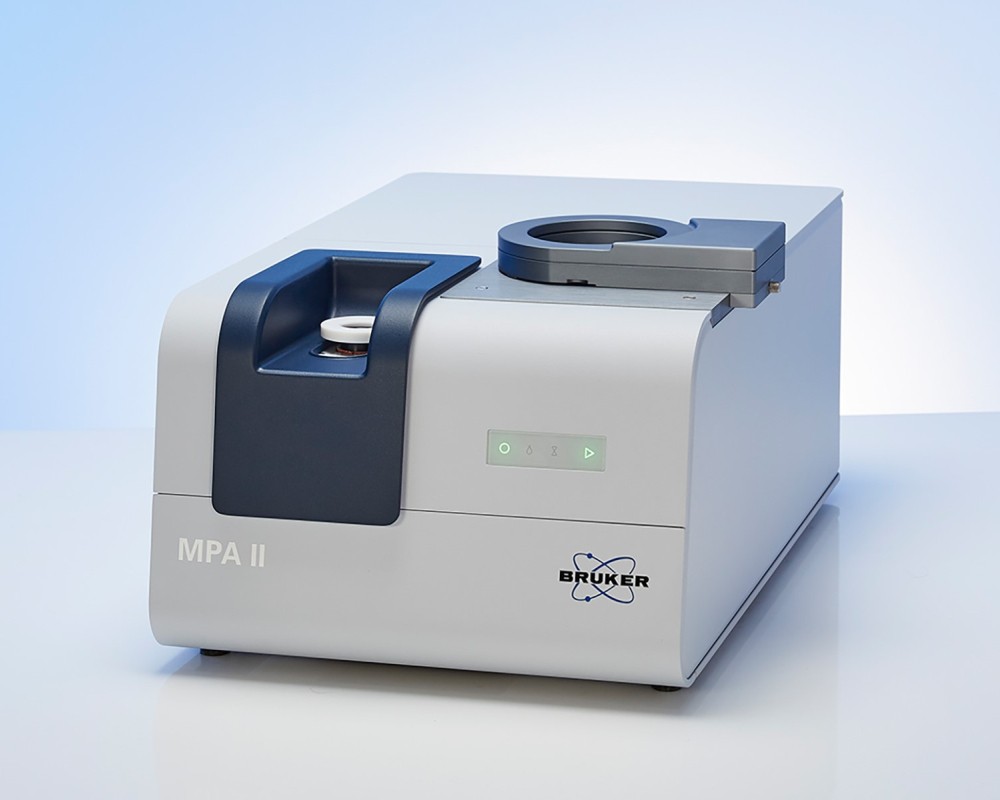

FT-NIR advantage

Near Infrared Spectroscopy is a well-established technique and today an important element of quality control in the food industry. Bruker Optics modern FT-NIR spectrometers can analyze both, liquid and solid samples and are the ideal tool for the non-destructive and rapid analysis of raw materials, intermediate and finished products throughout the entire manufacturing process.

FT-NIR offers a fast and simple tool for the analysis of a wide range of raw materials, intermediates and finished products in the food industry.

In contrast to most wet-chemistry and other reference methods the FT-NIR technology is quick, cost- effective, non-destructive and safe, since it does not use chemicals, solvents or gases. It simply measures the absorption of near-infrared light of the sample at different wavelengths recording molecular vibrations of all molecules containing C-H, N-H or O-H groups. By this NIR spectroscopy is the first choice for the analysis of all kind of organic materials, making it ideal for a wide variety of foodstuffs.

The key benefits of FT-NIR spectroscopy are:

- no sample preparation, no waste

- no special skills required, easy sample presentation

- no typical errors of classical lab methods

- analysis of multiple components in less than one minute

- suitable for any solid, semi-solid or liquid sample

Questions and concerns regarding food quality are endless, and the demand for easy-to-use tools to monitor and ensure the integrity of foodstuffs is growing around the world. FT-NIR is a powerful and effective technology for control of raw materials, intermediates and finished products. Common tasks in food processing are

- Identification of food ingredients and additives

Raw Material ID of food ingredients and additives

Food ingredients and additives have been used for many years to preserve, flavor, blend, thicken and color foods. Identification of these materials can be applied similar to the raw material ID in pharmaceutical industry for organic pure substances as well as some inorganic minerals and salts. Examples are: fats and fat replacers, carbohydrates, vitamins and nutrients, amino acids, enzymes and preparations, emulsifiers, stabilizers, thickeners, binders, texturizers, preservatives, sweeteners and sugar replacements.

In order to maintain an optimum balance between feed costs and productivity, all feed ingredients should be verified for nutrient concentration and these values are then used to formulate the rations and required supplements.

However, the used feedstuffs may differ widely in composition, due to origin, fertilizer use, seasonal changes, transport or storage. The raw materials delivered to the feed mill are likely to contain varying nutrient levels, depending on supplier, or even day of delivery.

Fourier Transform Near Infrared spectroscopy (FT-NIR) spectroscopy provides a fast and effective solution for analyzing raw materials as well as finished feeds in order to optimize the production steps and monitor the final product quality.

Optimizing the production of animal nutrition is vital, since it represents the largest operating cost for most commercial livestock producers. FT-NIR helps to deliver the best quality at lowest cost.

In contrast to most wet-chemistry and other reference methods the FT-NIR technology is quick, cost- effective, non-destructive and safe, since it does not use chemicals, solvents or gases. It simply measures the absorption of near-infrared light of the sample at different wavelengths recording molecular vibrations of all molecules containing C-H, N-H or O-H groups. By this NIR spectroscopy is the first choice for the analysis of all kind of materials on fat, protein, fiber, moisture ash and more, making it ideal for a wide variety of feeds, ingredients forages, and other foodstuffs.

The key benefits of FT-NIR spectroscopy are:

- no sample preparation, no waste

- no special skills required, easy sample presentation

- no typical errors of classical lab methods

- analysis of multiple components in less than one minute

- suitable for any solid, semi-solid or liquid sample

Quality control of feed ingredients and additives

Wheat as a raw material

To produce the optimum feed at lowest cost it is important to know everything about your raw materials. With FT-NIR spectroscopy, you receive the information you need for your feed formulation software in a matter of seconds rather than hours or days when using conventional technology.

Moreover, due to the speed and low cost of each single analysis, you can have a much tighter control on what is going into the finished feed, thus optimizing the feed quality and reducing out-of-spec production.

Our touch-screen operated TANGO FT-NIR spectrometer is ideal, even to use in the production area, since it needs no expert training and the user interface comes in 17 languages.