Established in 1968, PFERD-South Africa is a major player in the abrasive industry within South Africa and on the African continent. Kempton Park, Johannesburg is home to their head office and manufacturing facility and from here, they serve the entire sub-Sahara region.

The SA operation includes 5 sales and distribution offices situated across the country. PFERD-South Africa’s parent company, August Rüggeberg, situated in Marienheide, Germany, was founded in 1799. For over 50 years, PFERD-South Africa’s main goal has been to consistently supply industry with the highest quality products that offer the user maximum safety and comfort—living up to their philosophy of THERE IS NO SUBSTITUTE FOR QUALITY AND SAFETY.

As a founding member of the Organisation for the Safety of Abrasives (oSa), PFERD is committed to produce premium quality products that offers the user the highest level of safety. With over 9 000 products for surface preparation, finishing and cutting, PFERD offers a solution for various applications within a variety of industries.

PFERD’s dedication to technical expertise and constant improvement is evident through ongoing investment in their South African manufacturing facility as well as continuous research and product development. At their state-of-the-art PFERD Academy, training on product selection, safety and specific applications are offered free of charge with the objective of ensuring operator safety within the industry.

PFERD’s team of Application Specialists are available to assess your application and provide you with the optimum product and machine combination to ensure the ideal and most cost-effective solution. For additional information, or to arrange an on-site product evaluation, please contact PFERD-South Africa.

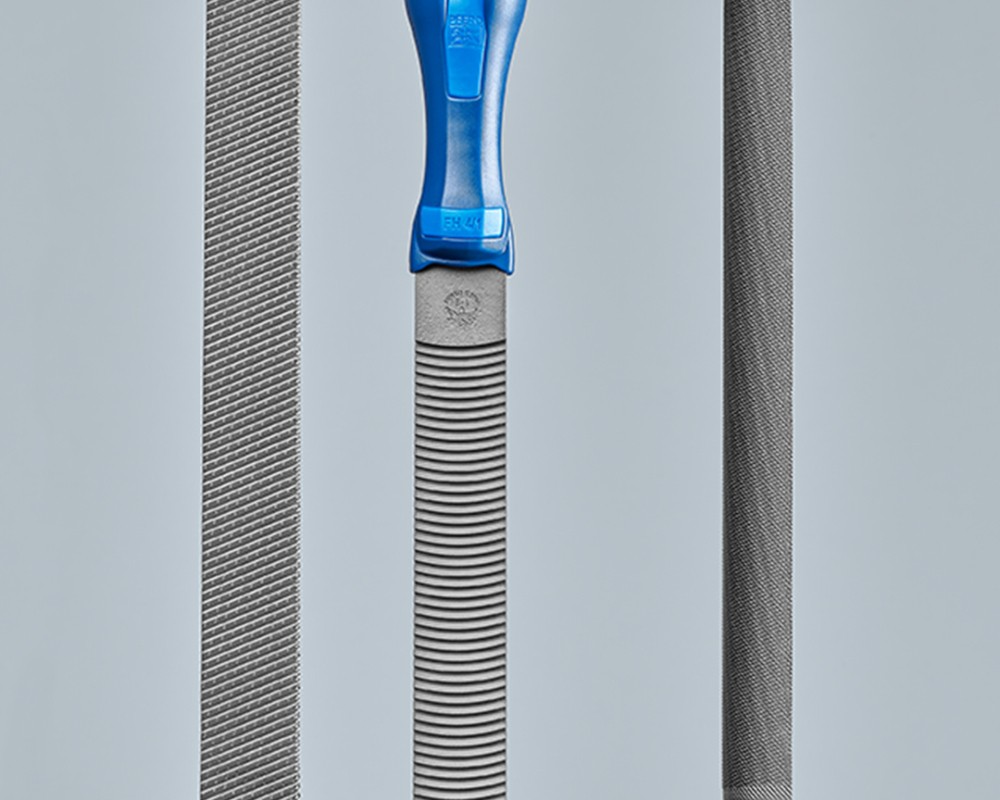

Files – Chamfering, Finishing and Sharpening

Milling Tools – Deburring

Machining of contours and Cutting out holes

Mounted Points – Machining of geometries

Chamfering and Cleaning

Fine Grinding and Polishing Tools – Creation of surfaces

Levelling and Polishing

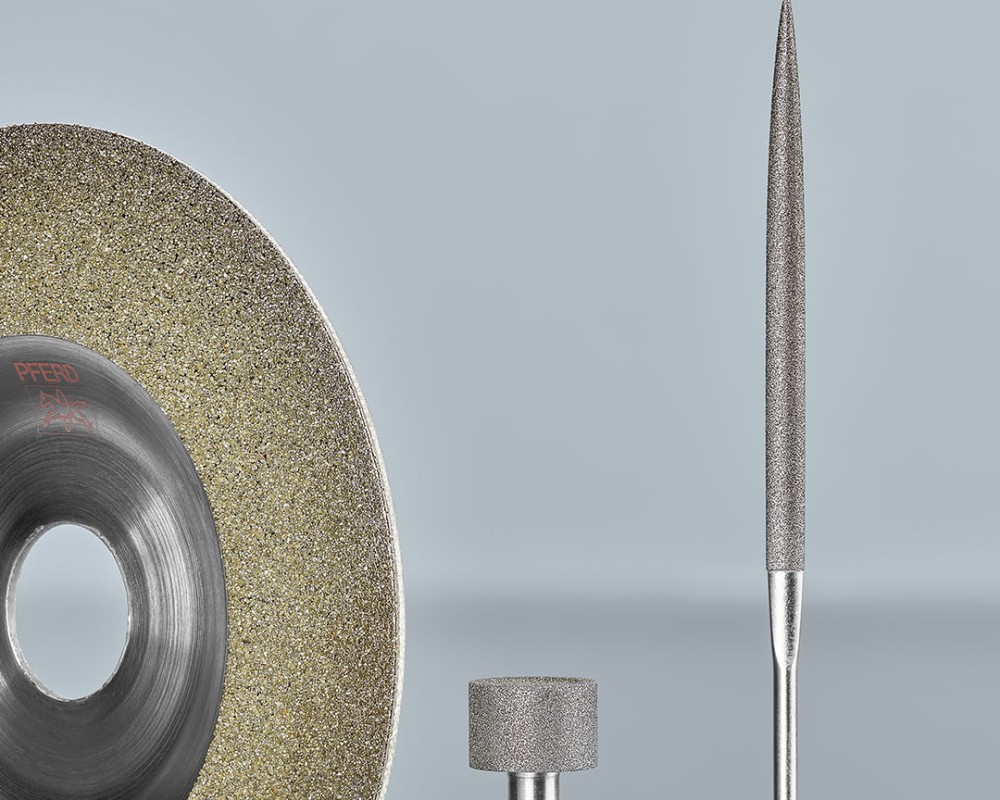

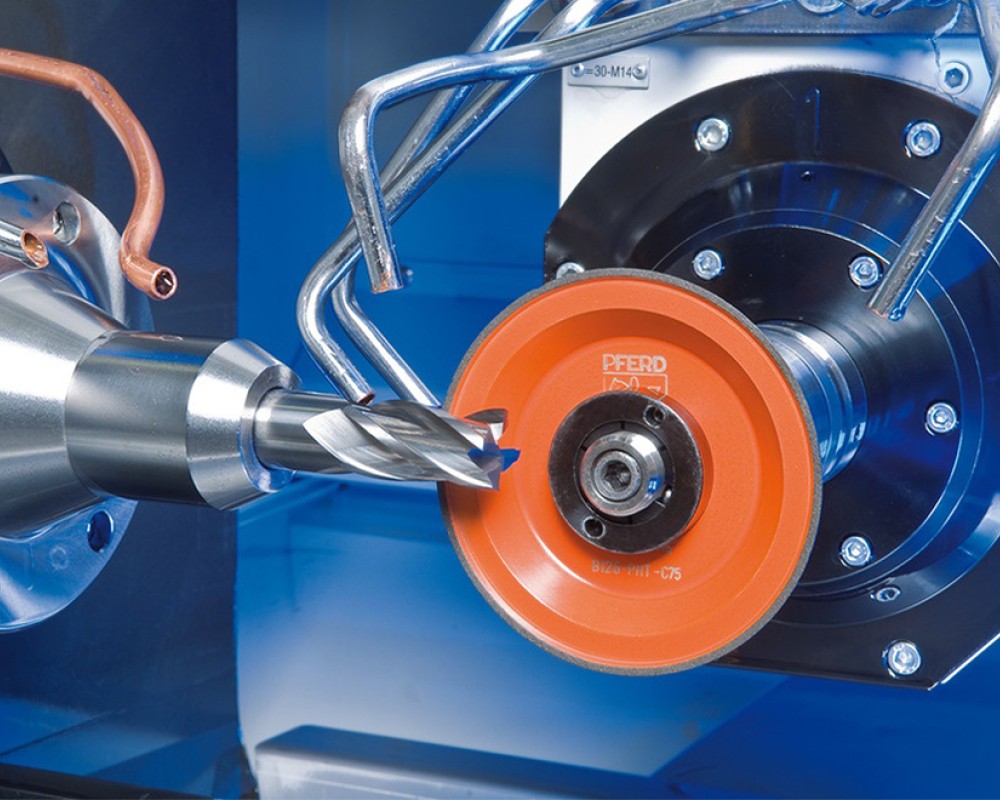

Diamond and CBN Tools – Filing

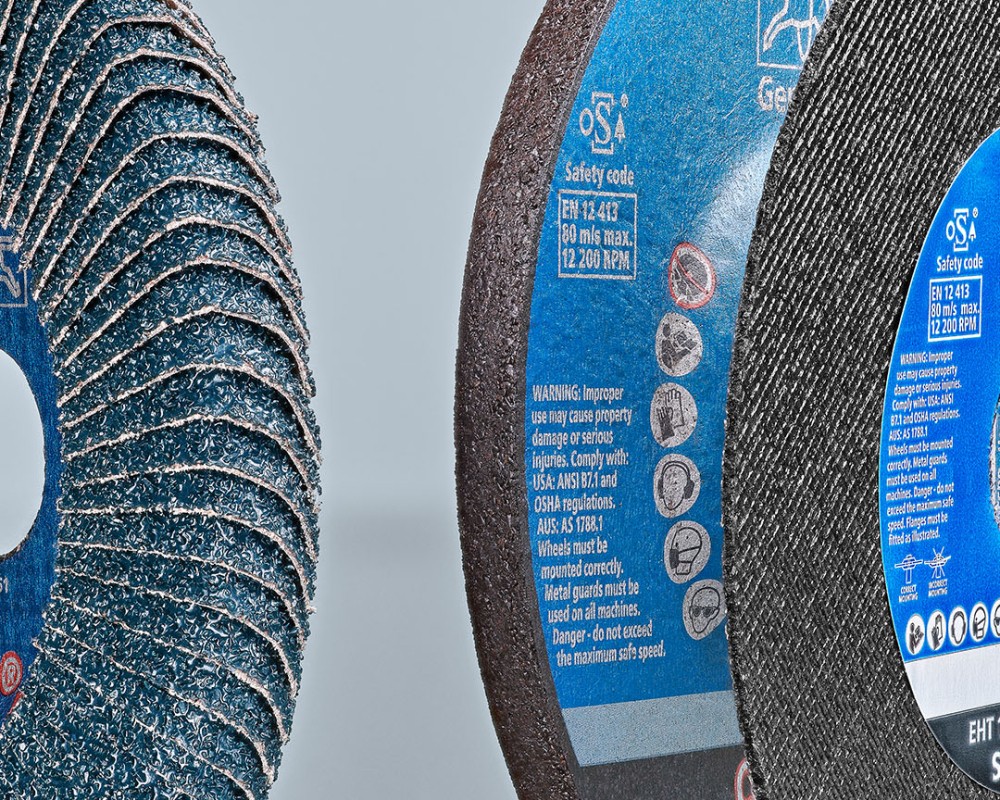

Grinding and Cutting Cut-off Wheels

Flap Discs and Grinding Wheels – Cutting

Roughing and Grinding

Cut-off Wheels for Stationary Applications – Cutting to size

Cutting of large cross sections and Cutting rails

Industrial Wire Brushes – Deburring

Cleaning of weld seams

Cleaning and Derusting

Tool Drives – Air grinders

Electric grinders and Flexible shaft drives