Plastic Ideas specializes in high quality plastic moulds and moulded products for local and export markets. We have been engaged in the manufacturing sector for more than 30 years.

We have utilized modern equipment such as CNC machining centers, EDM machines and EDM wire cutting machines. Modern CAD/CAM systems are in place to assure quality of moulds and moulded products.

With our innovative, dedicated and experienced team we can provide solutions to your product in development stage. Our engineering and quality assurance system guarantees your satisfaction in tool building and production moulding.

Value, reliability, quality, fast delivery and courteous service are what have earned us our customer loyalty. We welcome you to explore the possibilities

Quality Policy Statement

Plastic Ideas is committed to a policy of quality and excellence in order to realise its vision of becoming the leading supplier of injection moulded components and moulds in South Africa.

The Company’s QUALITY MANAGEMENT SYSTEM is therefore directed towards achieving the following objectives:

- To produce products, that is manufactured to the highest customer’s quality standards.

- To provide top quality service to the Company’s customers, by ensuring continuous improvement through monitoring and measuring customer satisfaction.

- To continue to support the profit objectives of the Company by optimising all available assets of the company to minimise losses.

- Recognising that the achievement of objectives depends on the development, commitment, experience and team work of all the people involved.

- To agree on clearly defined achievable goals for each team that will motivate the performance levels to achieve continuous improvement.

- To comply with the applicable laws, by-laws, regulations and compulsory standards of the Republic of South Africa.

We believe quality begins with mould design capability and consider it to be the key to successful mould making and final produce. At Plastic Ideas we have invested in both people and technology to ensure that our designs meet your highest expectations. As experienced mould designers we utilize the latest engineering software such as mould flow analysis to prevent weld lines and to eliminate over packing of tools which saves on material and clamping pressure.

Our engineering and mould making technology includes:

- Micro Scribe Arm (3D Digitizing)

- Mould Flow (Plastic Flow Analysis)

- CNC Machining Centers

- CNC Lathes

- CNC EDM’s (Electro Discharge Machining)

- Wire-Cut Machines

We have experience in most engineering plastics including synthetic rubber.

Moulding quantity: Plastic Ideas operates a very flexible service on supplying smaller quantities of parts with assembly and finishing. All moulds manufactured by Plastic Ideas used in-house are free of any maintenance cost.

- 3D component designing

- 3D digitizing (micro scribe)

- 3D tool designing

- Mould flow analysis

- Tool & die manufacturing

- Plastic injection moulding

- Component production assembly

- Mould surface graining (etching)

- Wire cutting

- Spark erosion

- Machining of electrodes

- Machining of punch and cavity

- Machining of large blocks/components

- CNC jobbing (turning & milling)

- CNC production (turning & milling)

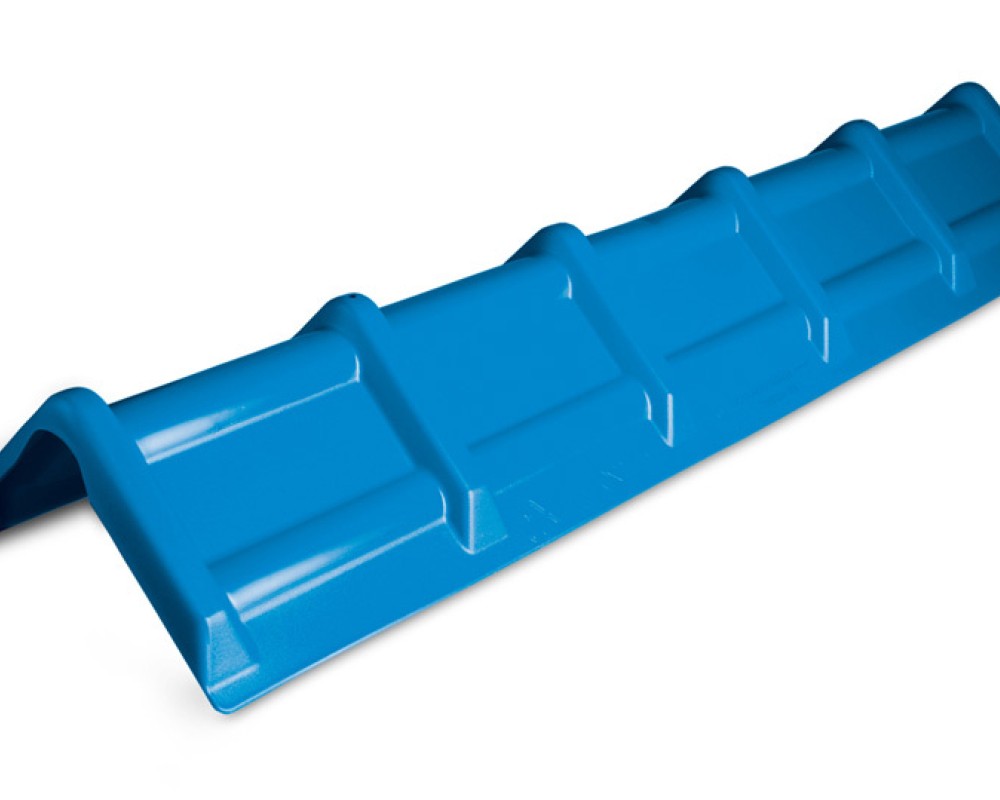

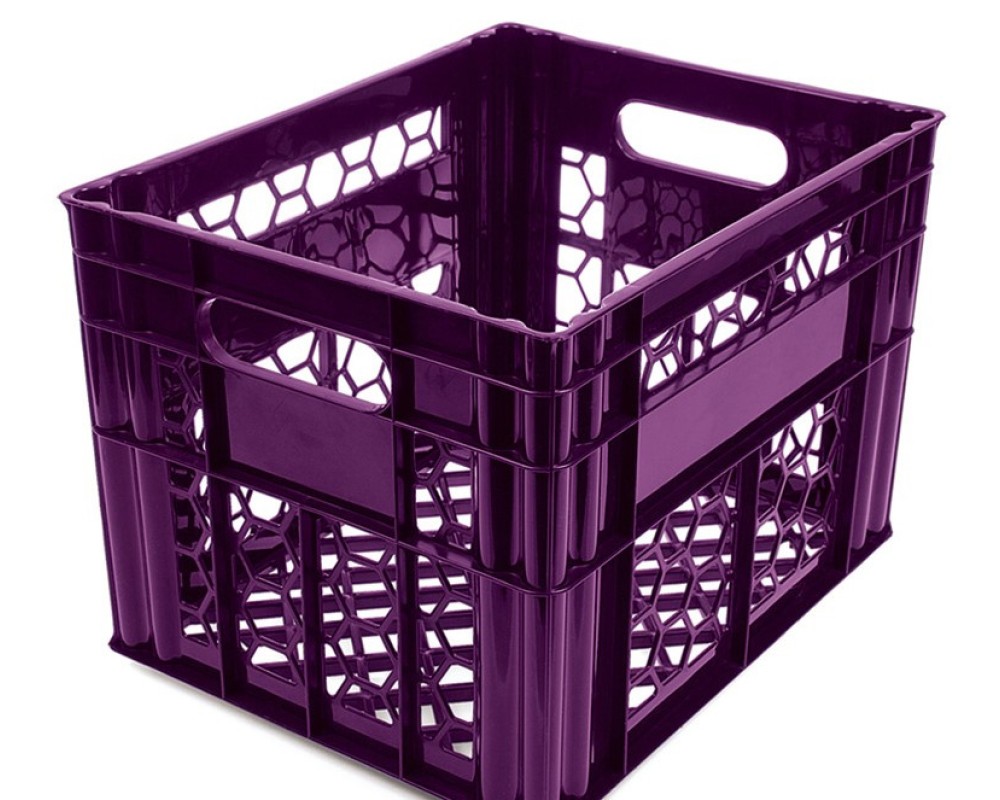

Plastic Injection Moulds

These are just a few of the moulds that we have produced for the various industries.

Mining Industry

- Polyurethane screens for shaker tables

- Snap on connector (screen assembly unit)

- Water sprayers

- Rock crushing tools

- Inline bricket press rollers

Motor Industry

- Runner boards

- End Caps

- Mud guards

- Nudge bar

- Trim pillar

- Steering wheel

- Steering column cover

- Center console

- Door handle

- Rubber Mats

- Polycarbonate lights, etc.

Packaging Industry

- Bottle crates

- Fruit & Vegetable crates

- Bread crates

Telecommunications Industry

- Outer casings

Manufactured for motorcycle wheels and other motorcycle components

Magnesium dies casting of sport wheels Low pressure dies casting of alloy wheels