WE ARE FIRMLY PLANTED IN AGRICULTURE

We are an independent company, a family, that cares more about building great irrigation systems than returning dividend to stockholders.

We value honesty, trust, common sense and tradition. If those things are important to you too, then you're already a part of the family.

WHO WE ARE

Galvanizing of Reinke systems is completed by ReinCoat, LLC a subsidiary of Reinke that boasts a state-of-the-art galvanizing facility and process. The process includes pre-treatment of the system components in a self-enclosed pre-treatment room. This pre-treatment is necessary to prepare the components for dipping into the zinc filled kettle contained in a white fume enclosure.

The end result of the galvanizing process from ReinCoat® is a superior protective coating that is ready to stand up to the elements, and further add to the strength and longevity of a Reinke irrigation system. ReinCoat, LLC is a registered ISO 9001:2015 company and is also a member of the American Galvanizers Association (AGA).

CENTRE PIVOTS

RUNNING CIRCLES SINCE 1968

What makes a Reinke system so special? Built from high strength materials, a Reinke system weighs less resulting in less stress on the drive train. This reduces the cost of ownership over the life of the system.

Irrigation in agriculture plays a significant role in the production of U.S. and World agriculture goods. Without the use of irrigation, crop production would be limited making it a challenge to meet the needs of a growing population.

Over the years many different irrigation techniques and methods have been developed to accommodate changing environments. Age-old surface irrigation still continues to be popular based on its simplicity and cost-effective value, but as technologies are changing mechanized irrigation systems are becoming more and more appealing to producers. Center pivot irrigation has become the most efficient and effective form of irrigation by using precision technology for many different applications throughout a field.

The future of irrigated agriculture will depend on the acceptance of changing technologies to increase precision management practices and enhance crop production. The value of efficiency and effectiveness is essential to maintain a sustainable agriculture environment.

Center pivot irrigation gives you the flexibility other irrigation methods are unable to provide. Center pivot irrigation introduces efficiency along with water management all while having a strong economic value.

Reinke offers a selection of 5 different types of water pipes, along with several different span lengths and diameters for every custom water application condition. With years of experience working with alternative materials, we will provide you with knowledge and expertise to ensure the best pipe material is selected to meet your irrigation needs.

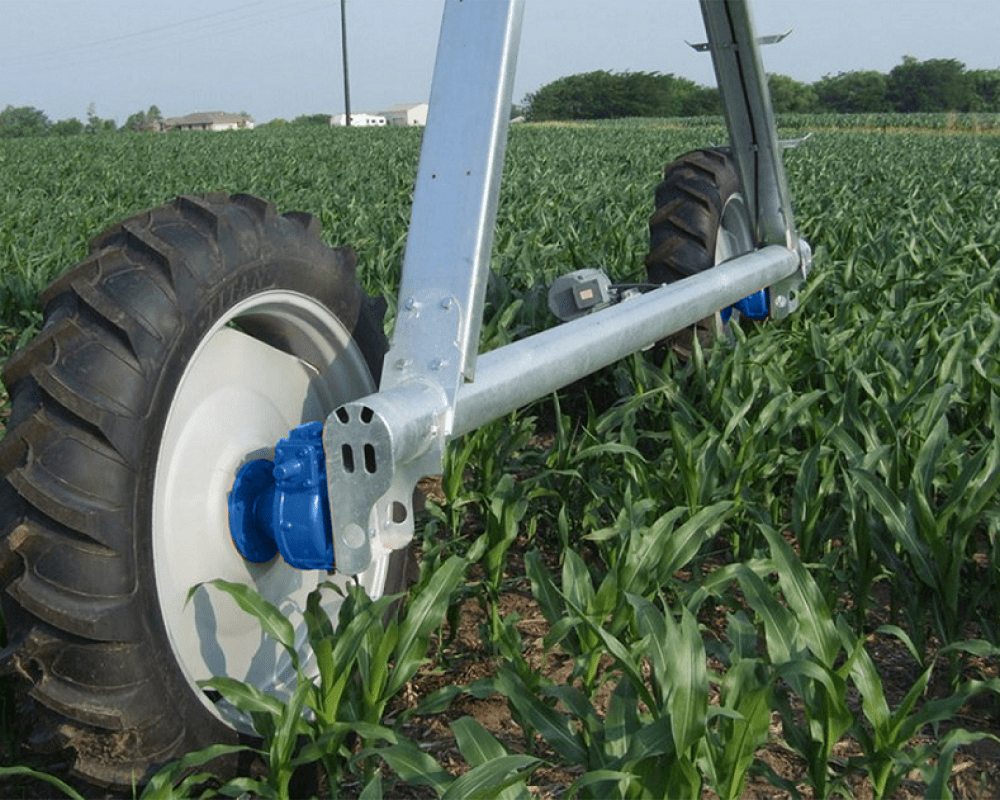

Our unique single-leg tower is the best in the industry.

Engineered to absorb stress that would normally be transferred to the pipeline, our tower design maximizes system life and reduces component fatigue – which means less wear and tear on the system, and less maintenance and ownership costs for you.

End Booms are available in several lengths (3', 13', 23', 32', 42', 51', 61', 85' and 105').

Truss rods and inverted truss supports provide the primary support for strength and stability. The 6" sand trap and control box, for the optional booster pump, are located near the tower for ease of servicing.

The booster pump itself is located at the end gun for maximum efficiency.

TURNING TO TECHNOLOGY

As technologies continue to evolve, so does the outlook on agriculture's precision management practices.

Incorporating precision agriculture into mechanized irrigation allows the use of different technologies to manage water applications, having accurate system locations, and the ability to remotely monitor and control irrigation systems.

COVERING EVERY INCH

When a Reinke center pivot or a lateral move system isn’t what you are looking for, you can be sure we have a specialty system that meets every one of your needs. Whether your field has unirrigated corners, is oddly shaped, demands frequent light applications or has an obstacle or two, we have just the right system for you.

NO MORE CUTTING CORNERS

Our Electrogator and Alumigator lateral move systems receive the same high quality materials and attention-to-detail engineering as the rest of our irrigation line. They also have enough custom features to match your exact needs. When the goal is watering your square or rectangular field while conserving water, look no further than Reinke.

GENUINE PARTS ON DEMAND

Reinke dealers carry a full selection of genuine parts to best fit any brand of irrigation system. Having a complete list of inventory parts makes it possible to get your system up and running in no time, as well as making any system updates or improvements.

WATERING CONSIDERATIONS

Reinke has always offered only the best sprinkler products to provide a multitude of droplet sizes and pattern widths using advanced rotary, offset axis rotary and fixed spray sprinkler technologies best suited for the specific crop or application. Whether you use our standard water pipe with 57" sprinkler outlet spacing or our LEPA (Low Energy Precision Application) water pipe with 40" sprinkler outlet spacing, we have the sprinkler products available that are capable of generating desired application rates. By utilizing a variety of plates, operating pressures, mounting heights and sprinkler spacing we can custom design a sprinkler package to virtually fit every field.

SOIL TYPE

Different types of soil need different types of irrigation. The difference in the water application rate is due to the rate at which water permeates through the soil and becomes saturated. It is important to supply enough water to maximize yield; however, it is also as important not to over-water as it can lead to yield reduction